Since 2007 we have been certified with our quality management system in accordance with DIN EN ISO 9001.

It is our goal to continue to improve the quality of our products through continuous optimisation and further development and thus go beyond merely satisfying our customers. We aim to exceed their expectations.

We want to create added value for our customers. To be able to do so, we do everything possible to continuously improve our services, processes and products in order to meet our quality requirements now and in the future. An efficient quality management system is the foundation of successful implementation. The system is firmly anchored across all levels of the company – and it is actively used everyday.

Hess pursues a zero-error strategy and is thus interested in the long-term prevention of errors. Please support us in our endeavour and contact our quality management staff if you have any product-related problems.

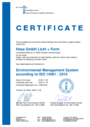

Since 2011 we have been certified with our environmental management system in accordance with DIN EN ISO 14001 – and since 2015, also in accordance with EMAS (Eco-Management and Audit Scheme), the seal of quality of the European Union. The EMAS stands for one of the most demanding systems for sustainable environmental management worldwide.

Compliance with legal requirements and regulations is a matter of course for us. In addition, due to our EMAS certification, we undergo an annual audit, which takes the form of a comprehensive environmental audit. Our environmental statement is publicly available. It is validated by an independent environmental verifier supervised by the State. The requirements of DIN EN ISO 14001 are part of EMAS – and accordingly, we also have an ISO 14001 certificate. Due to our EMAS certification we also fulfil the energy audit obligation in accordance with the Energy Services Act (EDL-G).

Recycling

The production of cast iron parts is a process that requires a great deal of energy but, depending on the intended use and processing, it allows the use of recycled material to a large extent. For example, grey cast iron parts – such as tree grates or cast grating and covers – are made of 99% steel scrap; and up to 95% recycled aluminium is used for conical aluminium poles, for example. In the aluminium foundry the percentage is lower, but the percentage recycled is still between 50 - 75%. The same recycling percentage applies to the steel which is used for the masts and the brackets.

At the end of a luminaire life cycle, the question of disposal in accordance with legal requirements arises. We are registered with Lightcycle and take back our old luminaires in order to dispose of them professionally. Lightcycle is an organisation for the return of end-of-life lamps and waste electrical equipment. The luminaires can be turned in free of charge to a Lightcycle collection point. For a total quantity of over one tonne, Lightcycle also collects the lights directly from our customers.

The nearest collection point and further information can be found using the following link:

Hess product lines offer numerous advantages. Let these inspire and convince yourself in your planning.

1. Advantage

Our products are a combination of superb function and quality aesthetics, adhering to the Bauhaus maxim “form follows function”. We realise challenging technical product features aesthetically. The availability of products in families provides immense creative freedom.

2. Advantage

The stringent design vocabulary of product families generates a uniform design and ensure their various integration in the scenery as well as a harmonious composition of urban space.

3. Advantage

The selective illumination of architecture with efficient technology and attractive design adds cultural value, art and further appreciate urban space.

4. Advantage

LEDs' significantly higher efficacy and longer maintenance intervals permit energy savings of 70% and more, which results in a considerable reduction of maintenance costs and a very attractive payback period.

5. Advantage

Key criteria for choosing the right light source are not limited to operating costs, but maintenance cost considerations also carry significant weight. Thanks to their long lifetime and their less frequent need for maintenance, these costs are very low with LEDs.

6. Advantage

Less light pollution means less nightglow and fewer disturbances of nocturnally active animals. The minimum proportion of UV light in LED light compared to previous lamp technologies makes LED sources significantly less attractive for insects. Animals are secured this way and the pollution of the luminaires reduced.

7. Advantage

Today's electronic ballasts are more efficient than earlier ballasts and enable a constant output.

8. Advantage

The manufacturing quality has a strong impact on the longevity of the luminaires. Poorly sealed housings permit the ingression of foreign particles, which decrease the luminous output of the luminaire. At Hess, we therefore attach great importance to the quality of our luminaires.

9. Advantage

LED-Lighting is basically steplessly variable. Using intelligent lighting controls therefore allows for adjustment of the luminaires to the respective lighting situations. Thus, dimming with different lighting levels and lighting that adapts to the traffic situation save a maximum of energy.

10. Advantage

Our dim systems are suitable for use with various LED modules and luminaires, and add to the already sizeable decrease in energy consumption and thus carbon emissions that LEDs provide.

11. Advantage

Besides energy savings, reduced light pollution, light beam image splitting technology delivers an exceptionally homogeneous distribution of light with an absolute minimum of glare.

12. Advantage

Recycling materials conserves resources. In the spirit of sustainability, most of the materials we use in our products are recyclable, which is another distinct advantage for the environment.